You’re staring at a 2400B mounted twenty feet up on a Max Menace arm when the DP suddenly calls to shift the key three feet stage left. Since fixtures like the Nanlux Evoke 2400B and 5000B are both powerful and heavy, repositioning becomes a full rigging operation that drains time, tires the crew, and sometimes reduces safety margins.

Fortunately, the NANLUX Motorized Yoke-L lets you adjust tilt remotely via DMX, eliminating the need to lower the light. As a result, whether you’re working on studio grids, condors, or large-stage productions, the workflow becomes faster, safer, and far more precise.

Key Features

- Fully compatible with Evoke 2400B and 5000B bi-color LED spotlights.

- Delivers 540° pan and 270° tilt with 40 N·m torque and self-locking stability (Data as of February 2026).

- IP66-rated magnesium alloy construction supports reliable all-weather operation.

- Offers multiple control methods including DMX, CRMX, NANLINK App, and on-board interface.

- Upgrades manual adjustments to safe, repeatable remote positioning for faster setups.

What Is the NANLUX Motorized Yoke-L?

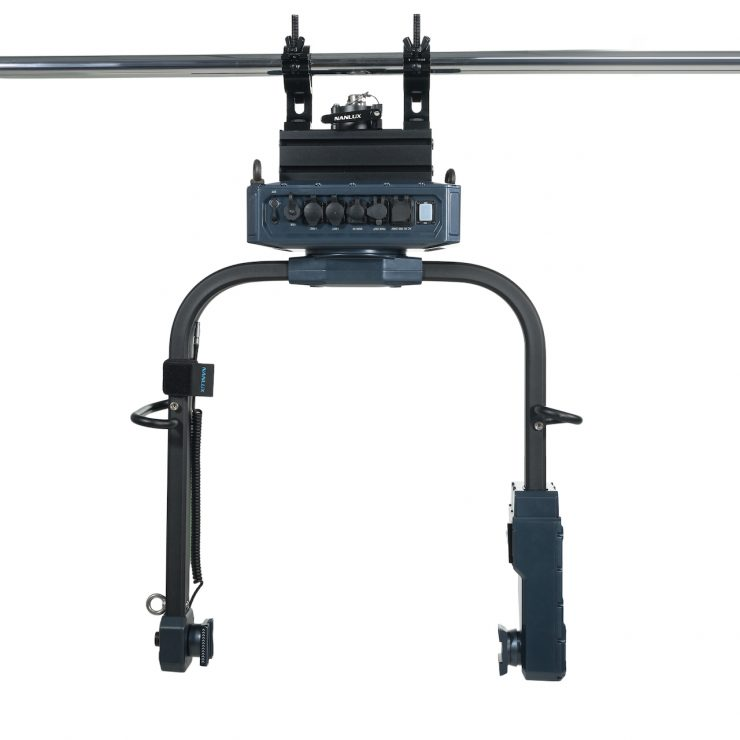

The NANLUX Motorized Yoke-L (YK-E-EVL) is a motorized tilt accessory designed specifically for the Nanlux Evoke 2400B and Evoke 5000B high-output LED fixtures. It replaces the standard manual yoke and allows remote tilt adjustment while maintaining the Evoke series’ IP66 weather protection.

Built for professional film, broadcast, and studio lighting setups, the Motorized Yoke-L delivers high torque and self-locking stability to support the heavy weight of these fixtures. It enables smooth, controlled movement under load, even when large modifiers are attached. When connected to a DMX lighting control system, tilt adjustments can be made remotely, improving workflow efficiency, safety, and repeatability on set.

Detailed Specifications of the NANLUX Motorized Yoke-L

1. Pan and Tilt Range

The NANLUX Motorized Yoke-L lets the light tilt up to 270° and pan 540°. This means you can move the light without touching the stand or the fixture. The movement is smooth even with heavy lights like the Evoke 2400B or 5000B. This makes it safer and faster to adjust lights on high grids, trusses, or outdoor setups. Quick adjustments save time during fast-paced shoots or changing scenes.

2. Heavy Load Support and Stability

This yoke is made to handle large, heavy LED lights safely. Its motors and self-locking system keep the tilt angle steady even if the power goes out. Always follow the manufacturer’s load limits when hanging lights on trusses, grids, or overhead rigs. The yoke keeps the light balanced and prevents it from moving unexpectedly, even when using large modifiers like Fresnels or softboxes.

3. Strong and Weatherproof Build

The frame is made from magnesium alloy, which is strong but light. The yoke has an IP66 rating, which protects it from dust and water. This means you can use it indoors or outdoors without worry. The size and shape are designed so heavy modifiers do not make the light unstable. This ensures safe and steady operation even in challenging setups.

4. Designed for Evoke 2400B and 5000B

This yoke is made just for the Nanlux Evoke 2400B and 5000B. It attaches with quick-release plates and connects to the fixture’s extension port. This keeps full output and color control while adding motorized tilt. The yoke keeps the light’s center-of-gravity correct, preventing tilt problems and mechanical stress. It is not a universal mount, it works best with these models for safe and reliable operation.

5. Remote Control and Workflow Integration

You can control tilt from a console or tablet using DMX512, CRMX, Art-Net, or sACN. There are also onboard buttons for direct control. The NANLINK App allows you to adjust the light from a smartphone or tablet. This makes it easy to set the same tilt angle repeatedly, which keeps lighting consistent across takes. Remote control reduces manual work and keeps production flowing smoothly.

6. Compatible with Accessories

The yoke works with the NL Mount system, which supports softboxes, Fresnels, and reflectors. You can swap accessories quickly without taking the yoke off. The tilt motor keeps the light stable, even with heavy modifiers attached. This makes fast changes on set easier and safer.

7. Saves Time and Improves Safe

Motorized tilt reduces the need for crews to physically move heavy lights. This lowers fatigue and risk of injury. On high grids, trusses, or outdoor setups, you can adjust lights without lowering them. This saves time, keeps the shoot on schedule, and protects both crew and equipment. The system improves workflow efficiency, repeatable positioning, and safe operation for professional productions.

Manual Yoke vs Motorized Yoke

| Manual Yoke | Motorized Yoke-L |

|---|---|

| Requires physical tilt adjustment | Remote tilt via DMX |

| Slower repositioning | Instant cue-based repositioning |

| Lower upfront cost | Higher initial investment |

| Minimal complexity | Requires power and control setup |

| Best for small crews or static setups | Best for dynamic, console-driven environments |

Pros & Cons

Pros

- Excellent weather resistance for outdoor reliability.

- Broad control ecosystem compatibility.

- Self-locking reduces drift risks.

- Quick mounting system speeds deployment.

Cons

- Added cost over standard yokes.

- Requires compatible Evoke fixtures only.

- Learning curve for advanced DMX/Art-Net programming.

Pricing & Availability of the NANLUX Motorized Yoke-L

The NANLUX Motorized Yoke-L typically sells for $1,500–$1,800 USD (Data as of February 2026), and you can purchase it directly from official NANLUX distributors, authorized resellers, or select online stores. To guarantee timely delivery for studio or location shoots, pre-order or confirm stock in advance.

The NANLUX Motorized Yoke-L is a motorized pan and tilt accessory for the Evoke 2400B and 5000B LED fixtures. It replaces the standard manual yoke, allowing remote-controlled, precise adjustments while maintaining structural stability and the fixture’s IP66 weather protection.

It is designed specifically for the Evoke 2400B and 5000B. Mounting geometry, weight balance, and torque specifications are optimized for these models to ensure safe and repeatable positioning.

Yes. It integrates with the NL mount ecosystem, allowing you to attach reflectors, Fresnels, or softboxes without removing the yoke. This streamlines workflow during fast-paced shoots.

Yes. The motorized yoke requires an external power source compatible with the Evoke fixture. Proper setup ensures reliable operation and avoids torque drift under load.

CREDIT – https://www.newsshooter.com/2026/02/12/nanlux-motorized-yoke-l-for-evoke-2400b-5000b/

https://www.redsharknews.com/nanlux-yk-e-evl-motorized-yoke-l-evoke-5000b-2400b